A year ago, I had an idea. What if we reuse scientific material instead of burning it? Sounds good right? Everyone I spoke to thought so too. Together with my good friend Frank, I decided to turn this idea into reality! But how do you turn your business idea into a real company? You need to validate your idea.

If we want to reuse or recycle scientific waste, it must be cleaned. And today, we’re going to find out how we can clean waste! We’re going to investigate which liquids are the best at removing pollution from scientific waste. Our focus question is: how can we purify disposables in the cleanest and most sustainable way? In other words, we are going to validate our business idea today!

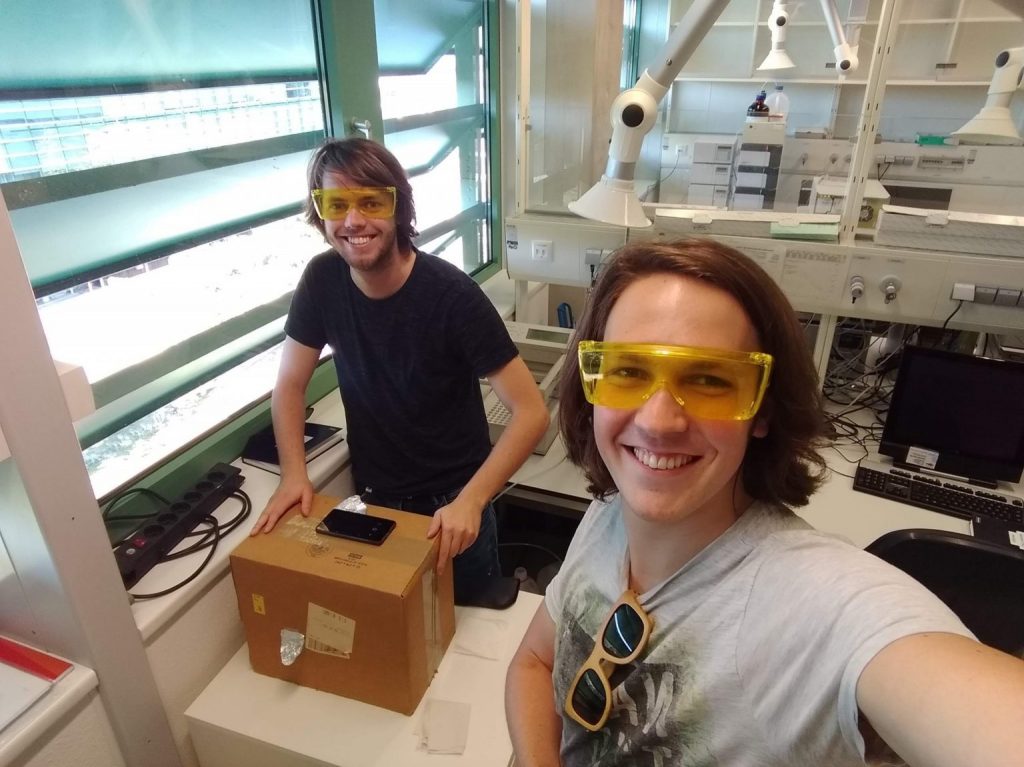

Filled with energy and light nerves, we arrived at the laboratory in the Huygens building at 8.30 AM. Way too early, but that worked out well in this case! Because while we were waiting, we ran into Jeffrey, who collects the waste every week. We talk to him about the tons of waste he collects from all the departments every week. “Oh, and if you want to know more, just stop by. I can give you a personal tour anytime!” Our day couldn’t have gotten off to a better start!

Sjoerd Rijpkema shows us around in the laboratory and we can immediately start our validation process! We begin by focusing on the UV lamps. We want to pollute the scientific waste, the disposables, with a fluorophore, so that we can detect even the smallest pollution under these lamps. After we have seen the UV lamps, we can get started with the pollution process. We put the disposables in a fluorophore solution, so that the liquid can attach itself to the disposables.

Next, we want to find out what the best way is to clean pipettes. Is this possible by using just water and a detergent? Or do we have to work with something heavier such as isopropanol? We put the pipettes and test tubes in the different solutions to see how much fluorophore (contamination) is still on the material. This way we can compare the different washing steps.

At the end of the day, all the disposables are in front of us. Tomorrow we can put them into the autoclave, a machine that can sterilize the material with pressure and steam. It’s a small start, but knowing what works will gives us the energy we need to keep going!

In the evening, we sit back, relax and think about the progress we made today. There is still a lot to be done tomorrow, but today we have taken a big step in our validation process!

Want to know more about Sustainables? Check out our company profile on LinkedIn!